Bag Production

Production

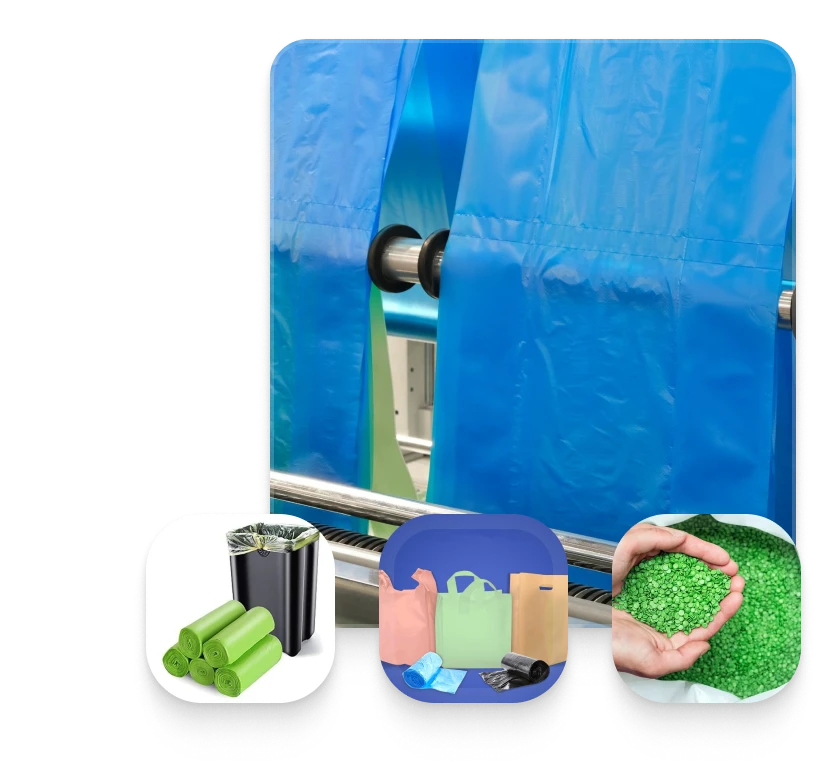

Plastic bag production typically involves processing polymer raw materials into the desired form. At CDB facilities, the production process consists of the following fundamental steps:

Bag Production

1. Raw Material Preparation

Polyethylene (PE) is commonly used in plastic ba g production. Polyethylene is classified into two main types: low-density polyethylene (LDPE) and high-density polyethylene (HDPE). Raw materials can include granules or recycled plastic materials.

2. Extrusion (Film Production)

The raw material is melted in extrusion machines to produce a film. During this stage:

- Plastic granules are heated and melted.

- The molten plastic is formed into a thin sheet (film) or expanded into a balloon shape by blowing.

- The film is adjusted to the desired thickness and size.

3. Cutting and Shaping

- The resulting plastic film is rolled and transferred to bag production machines.

- Shaping machines cut the film into the desired bag model.

- Details such as handle holes or reinforced handles can be added during cutting.

4. Sealing and Joining

- The sides, bottoms, or handles of the cut bags are sealed using heat-based joining methods to increase durability.

5. Packaging and Shipment

- The produced bags are inspected, folded, packaged, and prepared for shipment.

Types of Plastic Bags

HDPE Bags (High-Density Polyethylene):

- Thinner and more durable.

- Has a wrinkled surface.

- Used for supermarket bags, garbage bags, and produce bags.

LDPE Bags (Low-Density Polyethylene):

- Thicker and more flexible.

- Has a glossy surface.

- Preferred for shopping bags, custom-designed bags, and food packaging.

Biodegradable Bags:

- Made from materials that decompose more quickly in nature.

- An eco-friendly alternative.

Recycled Bags:

- Made from recycled plastic materials.

- Offers economic and environmental benefits.

Applications

1. Market and Shopping Bags:

- Widely used in supermarkets, stores, and markets.

2. Food Packaging:

- Bags designed to transport and protect food products.

3. Garbage Bags:

- Used for collecting household and industrial waste.

4. Courier and Packaging Bags:

- Ensures the secure transport of goods by courier companies.

5. Produce and Bakery Bags:

- Used to carry fresh produce, vegetables, fruits, and baked goods.

6. Promotional Bags:

- Custom-designed printed bags for brand promotion.

7. Industrial Bags:

- Durable bags used for transporting or packaging industrial products.

Plastic bags are used across a wide range of applications, from everyday life to industrial use. When properly recycled, their environmental impact can be reduced. By incorporating biodegradable and recyclable alternatives, the process can become even more sustainable.